So you’re thinking of a Colorbond roof and wondering what the minimum slope is for a Colorbond roof? For a corrugated Colorbond roof, which is a type of metal roofing, the minimum slope is 5 degrees. For a flat deck Colorbond roof it’s 1 degree and for monoclad roofs it’s 2 degrees. Following these minimum slope for Colorbond roof requirements is critical to ensure proper water drainage and no water pooling and leaks. In this article we will explain why and help you make an informed decision.

Roof Slope

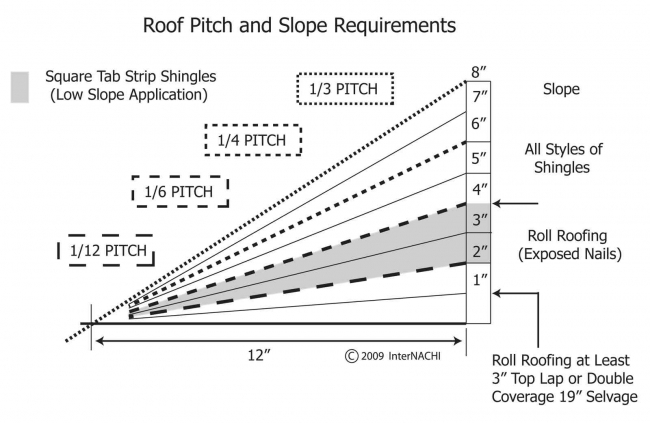

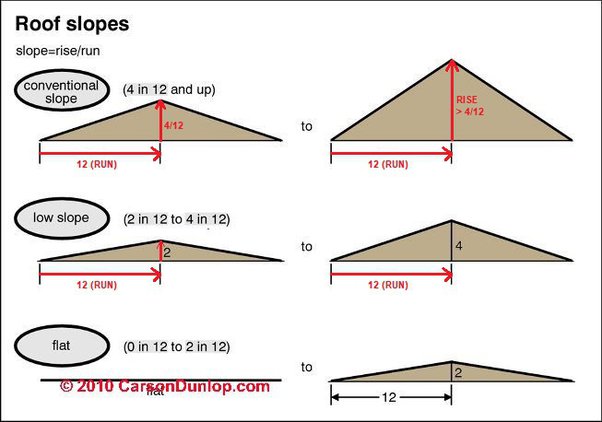

Roof slope is represented by a ratio like 1/12 or 5/12 and is a critical detail that determines how steep a roof is. It’s the vertical rise of the roof for every 12 inches of horizontal run. This is a key factor in construction and maintenance. Metal roofs, known for their superior performance and durability, are particularly effective in both high and low slope applications.

Low slope roofs often referred to as flat roofs have a slope between ¼-in-12 and 2½-in-12 and need a continuous waterproof barrier to prevent leaks. These are more common in commercial buildings but also used in residential. High slope roofs have a slope of 3-in-12 or more and are designed to shed water using gravity, so are ideal for areas with heavy rainfall.

The slope of the roof affects the choice of roofing materials, cost estimate and drainage calculations. For example some materials are better suited for high slope as they can shed water quickly while others are designed to provide a continuous waterproof barrier for low slope roofs.

Architectural style and the look of the building also comes into play when determining the roof pitch. For example traditional homes have steep slope roofs while modern designs have low slope or flat roofs for a sleek minimalist look. In some cases a pitched roof can be used to achieve a balance between the two.

Interpreting roof pitch is more than just numbers and measurements, it’s about how your roof will perform and look. Getting the right pitch whether for a classic sloped roof or a modern flat roof is critical for functionality and visual appeal.

Minimum Roof Pitch for Colorbond Roofs

For Colorbond roofs following the minimum slope requirements is key to ensure proper water drainage and no water pooling and leaks. A corrugated roof should have a minimum slope of 5 degrees, a guideline that allows for efficient drainage and no water leakage. This small angle is enough to get the water to flow off the roof and prevent any accumulation that can cause leaks.

The minimum slope for a flat deck roof is even lower at 1 degree. This small slope is known as the minimum roof pitch and is enough for deck roof sheets which have wide spans and high ribs to allow water to flow. Monoclad roofs need a minimum slope of 2 degrees. The design of monoclad roof sheets with multiple ribs ensures water drainage even at this low slope.

Following the minimum slope for your Colorbond roof is critical to avoid water related issues. Compliance to these requirements will prevent common problems like water pooling and leaks and ensures the roof will be durable and effective in protecting your home.

Minimum Pitch Factors

Several factors affect the minimum slope required for a roof. The local climate is one of them, the amount of rainfall and snow load will impact the slope needed for water and snow runoff. In areas with heavy rainfall a steeper slope is often required to get the water to drain quickly and efficiently off the roof surface.

The choice of roofing material also plays a big role. Different materials have specific slope requirements to work correctly. For example corrugated iron roofing has limitations when the slope is below 5 degrees which can affect its performance big time.

And the architectural style of the building also comes into play. Modern designs may prefer flat roofs for a sleek look while traditional styles may require steeper pitch to maintain the classic look. Knowing these factors and the roof structure will help you make informed decisions when planning your roof.

Australian Standards

Compliance to Australian standards and local regulations is key to compliance and safety in roofing projects. Every Colorbond sheet comes with a full warranty which means they comply to these standards and can withstand extreme weather conditions. This compliance ensures the durability and reliability of the materials used.

Fixing a non compliant roof can be a complicated process. It involves:

- Removing the existing roof

- Regrading with metal or timber battens

- Installing safety mesh and insulation

- Fitting new roofing materials

- Ensuring the building’s structural integrity

- Checking for additional support for steeper pitches

These are the steps to fix a non compliant roof.

Using the right fasteners is another critical aspect of compliance. Fastening screws should be AS3566 – class 3, hexagon headed and used with sealing washers to ensure secure installation. By following these guidelines you can ensure your Colorbond roof meets all Australian standards and performs optimally.

Installation Tips for Low Pitch Colorbond Roofs

Proper installation is key to getting a watertight and long lasting low pitch Colorbond roof. Using Class 4 screws designed for outdoor use is recommended for optimal installation. Screwing through the crests of the sheets will give you maximum water tightness and prevent leaks.

Sealed joints are critical to the integrity of the roof. Here are the tips for sealing the joints:

- Use screws or rivets to secure the joints.

- Use neutral-cure silicone sealant for galvanized or zincalume steel to seal the joints.

- Have a 50mm overhang into the gutter to ensure water drains properly and water doesn’t seep back under the roof sheets.

Proper side-lap is another critical aspect. Overlapping the sheets by at least 1.5 corrugations will give you a secure and watertight joint between the sheets. Installing a vapor barrier under blanket insulation will prevent moisture penetration and protect the building from dampness. Considering thermal expansion you need to account for material changes during temperature fluctuations.

When laying the roof sheet follow these steps:

- Start from the end of the building that is least exposed to the prevailing weather to get maximum weather tightness.

- Wear heavy-duty, cut-resistant gloves and use proper manual handling techniques to prevent injuries and damage to the sheets during installation.

- Place bundles of roof sheeting over firm supports rather than at the mid-span of roof members when lifting them onto the roof to avoid bending or damaging the sheets.

By following these steps you will not damage the sheets.

Colorbond for Low Pitch Roofs

Using Colorbond for low pitch roofs has many benefits. Colorbond sheets are made from 100% Australian made BlueScope steel and meets local production standards and quality. Colorbond is designed to withstand harsh weather conditions and suitable for all Australian climates.

One of the benefits of Colorbond is:

- Lightweight, safer than heavier roofing materials

- Water and snow runoff even on low pitch roofs due to its metal construction

- 22 modern colours to match your style.

Colorbond has:

- Durability

- Low maintenance

- Many colours to choose from

- Fire protection so it’s safe to use in bushfire prone areas

These makes Colorbond perfect for low pitch roofs, durability, safety and style.

Common Problems and Solutions for Roof Leaks

Low pitch roofs can have many common problems but with regular maintenance and proper installation these can be minimised. Roof leaks is one of the common problems, often caused by poor installation or extreme weather. Ensure all joints are sealed and the roof is installed correctly to prevent leaks.

Water pooling and puddling on low pitch roofs can cause mold and structural damage if not drained properly. To prevent this:

- Regularly check and clean the roof to remove any debris buildup, leaves and branches.

- Ensure the roof has proper drainage to prevent water from pooling.

- Consider installing gutter systems or roof drains to direct water away from the roof.

- If necessary, call a professional to assess the roof slope and recommend any modifications.

By doing this you will prevent water damage and extend the life of your roof.

Inadequate ventilation on low pitch roofs can cause heat and moisture buildup leading to mold growth and roof decay. Proper ventilation will help maintain the roof integrity. Animals like rodents and birds can damage the roof by clogging gutters and tearing holes on roofing materials. Regular maintenance and inspections will help you identify and fix these problems early so your low pitch Colorbond roof will last and perform well.

Roofing Profile Selection

Choosing the right roofing profile is crucial for your roof’s performance and life. The pitch of the roof is the most important factor to consider. Not all profiles are suitable for pitches below 5 degrees. For pitches below 5 degrees you need to use profiles designed for flat roofs.

The base metal thickness (BMT) also affects the strength and durability of the metal roof. Corrugated profiles such as corrugated roofing is a safe choice for most roofing needs, it’s strong and durable. Metal sheet roofing, especially Custom Orb steel roofing is suitable for low pitch roofs and high rainfall areas, it’s a great choice for corrugated roofs. It has better damage resistance, greater spanning capacity and available in Colorbond and Zincalume finishes.

Using the right materials and profiles will ensure the roof can withstand the local climate and load requirements. By considering these you can choose a profile that meets your needs and performs long term.

Style with Colorbond Roofs

Colorbond roofing adds style to a building by offering many styles and designs. The end look of the roof, colour, texture and style will affect the overall look of the building. For example using warmer colours will blend the roof with the surrounding landscape and create a rural retreat look.

Contrasting colours and materials will create a classic or modern façade and add character to the building. Some options to consider are:

- New Colorbond steel cladding profiles

- Render

- Feature brick

- Colorbond steel walling

These will give maximum impact on feature walls or a whole level and make the design unique. Combining different materials will add texture to the exterior palette and make it more aesthetically pleasing.

Horizontal Colorbond steel walling and pale cool tones will work for coastal inspired designs, youthful cool palettes or Matt finish wall cladding will work for a compact single level house. By choosing the right colours, textures and materials you can create a beautiful and unique look for your home with Colorbond roofing.

Conclusion

Knowing the minimum pitch for Colorbond roofs is important to ensure proper water drainage and prevent leaks and water pooling. By following the minimum pitch requirements and considering local climate, materials and architectural style you can make informed decisions for your roofing project.

Compliance to Australian standards and proper installation is key to the durability and performance of your Colorbond roof. Using the right profile and styling with Colorbond will add both functional and visual value to your home.

Ensure that your Colorbond roof offers superior protection and style for your home by following this guide. For expert advice and professional service, contact Fremantle Roofing Service. We specialize in Colorbond roof restoration and roof repairs, guaranteeing quality and durability that stands the test of time. Trust us to bring the best out of your roof—reach out today.

FAQ

What is the minimum pitch for a Colorbond corrugated roof?

5 degrees

Why is pitch important?

Pitch is important because it affects drainage, material choices, cost and the overall look of the building.

How does climate influence pitch?

Climate influences pitch by the required pitch for water and snow runoff. Heavy rainfall or snow loads will require a steeper pitch to ensure drainage.

What are the benefits of Colorbond for low pitch roofs?

Colorbond is good for low pitch roofs because it’s lightweight, durable, fire resistant and can handle water and snow runoff on low slopes. It’s suitable for those roofs.

How do I make sure my Colorbond roof is compliant to Australian standards?

Make sure to follow local regulations, use Colorbond steel and follow proper installation practices, such as using fastening screws that conform to AS3566 – class 3 and all materials meet Australian standards.

Leave A Comment