Understanding roof Australian standards and building regulations is essential for anyone involved in construction or roof restoration and renovation. The AS 1562.1:2018 standard lays out the crucial guidelines for designing and installing metal roofs and wall cladding.

This article breaks down what you need to know about these standards to ensure your roof is safe, durable, and compliant.

The updated standard, AS 1562.1:2018 – Design and Installation of Sheet Roof and Wall Cladding – Metal, serves as a guiding light leading the industry towards the pinnacle of structural integrity and durability.

It serves as the cornerstone for safety, setting out requirements for the design and installation of self-supporting metal roof and wall cladding, particularly under the strains of out-of-plane loading.

The Standards Australia Handbook is designed to enhance this standard, offering practical guidance on the selection, performance, and installation of metal roof sheeting and wall cladding.

It provides valuable information to support the application of the standard in real-world scenarios. As we examine these standards, we’ll investigate their influence on the planning and implementation of projects throughout different regions of Australia.

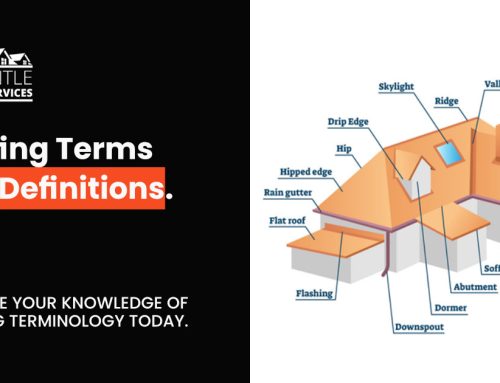

Overview of Australian Standards for Roofing

The Australian landscape, with its striking diversity, spans from arid deserts to lush tropical rainforests. Such diversity demands a roofing standard that can rise to the occasion, ensuring that every metal roof and wall cladding can withstand the specific challenges it may face. Enter AS 1562.1:2018, the Australian Standard that provides the blueprint for the design and installation of metal roofing and wall cladding.

This foundational standard transcends simple guidelines, constituting a sturdy framework that prioritizes safety and durability against out-of-plane loads like wind loads and snow. Officially titled ‘Design and Installation of Sheet Roof and Wall Cladding – Metal,’ it is the result of years of expertise distilled into a document that sets the bar for roofing excellence across Australia.

Backed by the Standards Australia Handbook, professionals engaged in roofing projects gain essential insights to choose suitable roofing materials, thereby ensuring every metal roof and wall cladding is capable of safeguarding and enhancing buildings nationwide. As we explore the recent updates to this key standard, we’ll understand how it continues to evolve with the industry’s needs and the importance of properly undertake roofing projects.

Key Updates in AS 1562.1-2018

Stagnation hinders progress, and the revisions in AS 1562.1:2018 embody the continuous pursuit of advancement in the metal roofing and wall cladding industry. These significant updates have honed in on material quality, ensuring that only the finest components are used in construction. The standard also considers the thermal performance of materials, ensuring they can withstand temperature variations without compromising structural integrity. The standard now addresses critical load-bearing aspects, considering factors such as frictional drag in wind and the behavior of materials under snow loadings.

The inclusivity of AS 1562.1:2018 is apparent in its application to both cyclone and non-cyclone regions, providing essential guidelines for constructing self-supporting metal roofs that can endure the unique challenges of each area. Installation techniques, too, have received a facelift, with the standard specifying best practices for fastening that enhance the security and durability of metal roofs.

With these updates, the standards not only keep pace with the developments in the industry but also lead the charge towards safer, more reliable metal roofing solutions. We cannot overemphasize the significance of compliance, as it acts as the lynchpin guaranteeing the longevity and safety of our roofs, as we will discover shortly.

Importance of Compliance with Roofing Standards

Compliance with the building code is not a mere formality; it is the cornerstone of industry practice that upholds safety and structural integrity, preventing costly setbacks. Adhering to AS 1562.1:2018 is not optional; it is mandatory for all new building projects, binding property owners to a legal obligation that cannot be ignored. This is not just about following rules; it’s about protecting lives. By complying with Australian building standards for roofs, property owners ensure the safety of occupants and maintenance personnel alike.

A roof that is built to standard is a bulwark against the elements. It is designed to withstand harsh weather conditions, thus significantly improving its durability. Failure to comply with these standards can have serious implications, from delays in council approvals to expensive design changes that can derail building projects.

Building surveyors, positioned at the intersection of design and compliance, play a crucial role in the certification process. They are the guardians of standards, ensuring that each metal roof installation meets the stringent requirements set forth by AS 1562.1:2018. For property owners, being aware of these standards, especially concerning performance solutions and compliance outcomes, is of utmost importance.

Now, let’s shift our focus to those stakeholders who must stay abreast of these standards to facilitate a smooth construction process.

Who Should Be Informed About These Standards?

Knowledge is most potent when it is shared, especially when it comes to the rigorous standards set by AS 1562.1:2018 within the construction industry. Everyone involved in the supply, design, and construction of metal roof and wall cladding must be aware of these guidelines. Builders, plumbers, sheet roof and wall installers, and manufacturers form the core group of primary users of the Handbook, which elucidates the fine points of the standard.

Builders and installers, in particular, must guarantee that their craftsmanship aligns with the detailed guidelines of AS 1562.3, covering everything from material selection to the nuances of installation techniques. Roofing plumbers, another crucial link in the chain, bear the responsibility of ensuring that their plumbing work meets the current standards for compliance. Developers and architects, too, must navigate these waters carefully, ensuring their designs are not only innovative but also in strict adherence to the updated standards.

As we peel back the layers of best practices and requirements, it becomes clear that a broad spectrum of professionals must align themselves with these standards. With the right installation techniques for metal roofs, the longevity and performance of these structures can be greatly enhanced, as we will explore in the following section.

Installation Techniques for Metal Roofs

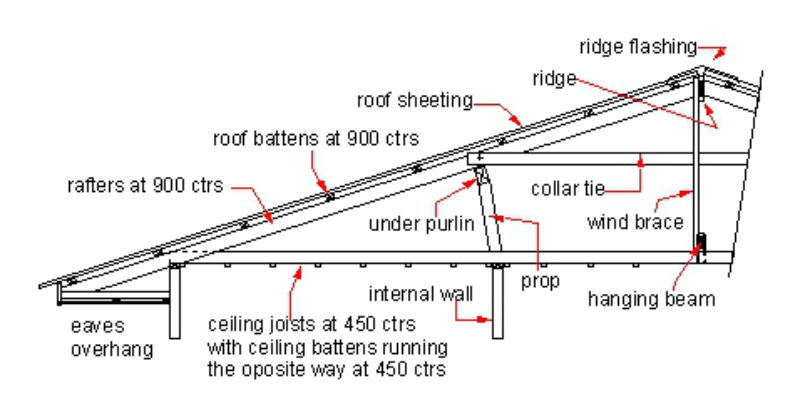

Installing a metal roof mirrors conducting a symphony, requiring every element to harmonize perfectly with the rest. AS 1562.1:2018, the installation code, is the conductor’s baton, guiding installers through the intricate movements of best practice design and installation techniques for metal roofing and wall cladding. Proper weatherproofing techniques are essential to prevent water ingress and ensure the longevity of the roof. From the gentle slopes that guide rainwater away to the precise lapping that ensures a watertight seal, the standard covers a wide array of details such as roof slope, pitch, and the art of bull nosing and curving roofs to perfection.

Yet, it is perhaps in the realm of roof flashing and capping where the finesse of these techniques truly shines. Flashings are the unsung heroes, meticulously crafted to prevent water ingress at the joints and edges of metal roofs. These critical components, when installed correctly, can make the difference between a roof that endures and one that succumbs to the elements.

Each step, from the aligning of sheets to the securing of ridges, must be undertaken with precision and care. The installation of metal roofs is not just about covering a building; it’s about crafting a shield that stands guard against the vagaries of weather, ensuring the safety and comfort of those beneath it. With the proper techniques, a metal roof can become a lasting testament to the installer’s skill and the industry’s commitment to quality.

Material Compatibility and Durability

Selecting materials for a metal roof goes beyond mere aesthetics; it significantly influences the roof’s lifespan and performance. The Standards Australia Handbook, specifically HB 39-2015, provides comprehensive guidelines on material thickness, compatibility, corrosion resistance, and the durability of steel, along with the critical selection and application of sealants. These guidelines ensure that materials are not only compatible to prevent corrosion but also chosen for their enduring quality.

In the realm of corrosion, knowledge is power. Understanding the factors that affect the corrosion rates of steel is essential for ensuring the longevity of roofing materials. With Australia’s varied atmospheric conditions, the corrosion rate of mild steel can range from a mere 1.3 to a staggering 200 µm/year, depending on whether the environment is a remote inland or an aggressive industrial area.

This variance in corrosion rates underscores the need for meticulousness in material selection, particularly when it comes to fasteners, fixtures, and the contact between different metals. The interplay between copper and galvanized coatings, or lead and aluminum/zinc coatings, must be carefully considered to prevent the detrimental effects of corrosion, as outlined in the standards.

As we pivot from the considerations of durability and compatibility, we move towards another critical aspect of roofing – the stormwater drainage system.

Stormwater Drainage System Requirements

The stormwater drainage system, a silent yet vital component of any roofing structure, efficiently handles the onslaught of water that nature unleashes on a building. Effective waterproofing is crucial to ensure that stormwater is efficiently conveyed away from the structure, preventing potential damage. AS 3500.3 is the standard that delineates the requirements for materials, design, installation, and testing of these systems, ensuring that stormwater is efficiently conveyed away from the structure.

This standard is a comprehensive guide that spans the spectrum of stormwater management, from the selection of durable materials to the intricate design of efficient drainage systems. HB 39-2015 further supports this by providing guidelines that ensure metal roofing and wall cladding are installed to facilitate proper stormwater drainage. The installation of gutters, downpipes, sumps, and rainheads is an art in itself, one that is governed by the rigorous guidelines set forth in the standard.

The effectiveness of a stormwater drainage system is not just about its installation; regular cleaning and maintenance are just as crucial. Gutters choked with leaves or downpipes clogged with debris can lead to water pooling on metal roofs, accelerating corrosion and potentially causing structural damage. With proper attention and care, these systems can function seamlessly, ensuring the roof above remains dry and secure.

As we consider the specific needs of non-cyclone regions, the principles of material compatible solutions and corrosion prevention remain paramount.

Specific Considerations for Non-Cyclone Regions

Although cyclones are a powerful threat, the temperate environmental conditions of non-cyclone regions pose their distinctive set of challenges. AS 1562.1:2018, with its application to both cyclone and non-cyclone regions, balances the needs of these diverse environments. In non-cyclone areas, the focus shifts to material compatibility and corrosion prevention, with the standard specifying requirements that are tailored to these less turbulent but equally demanding conditions.

The interplay between different metals on a roof, especially in non-cyclone regions, is a delicate dance that must be choreographed to perfection. Metals must not only be compatible to avoid galvanic corrosion but also chosen with an eye towards the surrounding environment and its potential impact on the roofing materials. Understanding the nuances of these requirements is crucial for anyone involved in the roofing industry in these regions.

By adhering to the specifics outlined in AS 1562.1:2018, builders and installers in non-cyclone regions can ensure that the roofs they construct are not only built to last but also built to protect. As we move on to discuss the maintenance and safety guidelines, it becomes clear that the longevity of a metal roof is not solely reliant on its initial installation but also on the ongoing care it receives.

Maintenance and Safety Guidelines

Similar to a finely-tuned engine needing routine check-ups for smooth operation, a metal roof requires regular inspections and maintenance to maintain its performance and durability. Regular preventive maintenance can identify signs of wear, corrosion, or damage early, allowing for prompt interventions that can significantly reduce long-term maintenance costs. Repainting and resealing are more than cosmetic touch-ups; they’re essential measures that protect metal roofs from the elements.

The significance of professional roofing services in the consistent maintenance of metal roofs is undeniable. By engaging experts for periodic inspections and maintenance, property owners can rest assured that their roofs remain in optimal condition. This is not just a matter of preserving the building’s appearance; it is a commitment to safety and longevity that should not be taken lightly.

The guidelines laid out in the Australian Standards for roofing serve as a roadmap for maintaining the integrity of metal roofs. By following the maintenance and safety solutions outlined in these standards, property owners and industry professionals can aim to extend the life of their roofs and ensure they continue to provide shelter and security for years to come. As we conclude our exploration of these standards, let’s summarize the key takeaways and address any lingering questions.

Summary

Our journey through the world of Australian Standards for roofing reveals a landscape where precision, quality, and adherence to industry standards form the bedrock of the industry. The AS 1562.1:2018 standard is the cornerstone of this domain, providing a comprehensive reference for those looking to ensure the safety, durability, and compliance of metal roofing and wall cladding. By understanding and applying these standards, industry professionals can craft roofs that not only meet the rigorous demands of the Australian climate but also stand as a testament to their commitment to excellence. May this knowledge serve as a beacon for all who seek to uphold the integrity of our buildings and the safety of those who dwell within them.

For professional roofing services that adhere to these high standards, consider Fremantle Roofing Services. Our expert team is dedicated to delivering top-quality roofing solutions that ensure safety, durability, and compliance. Contact us today to learn how we can help you achieve the best results for your roofing projects.

Leave A Comment